Since 2010, Cyndar has been committed to safety sensors. We insist on technological innovation and put customer success first. A professional pre-sales team will guide customers on how to choose the most suitable products.

Announcement: Cyndar is tracking the company's actions in response to the COVID-19 crisis and improving best practices to incentivize better business behaviors. We voluntarily reduce profits to help companies through their sadness. We sincerely wish you health

Safety light curtain sensor, safety light curtain sensor used to determine the position

- Safety light curtain safety grating sensor

- CCT universal safety light curtain sensor

- CRFT Waterproof Safety Light Curtain Sensor

- QX short-distance economical safety light curtain sensor

- CAT remote sensing safety light curtain sensor

- CST stamping safety protection safety light curtain sensor

- CSAT multi user detection mirror column safety light curtain sensor

- CBT/CZT ultra-thin compact safety light curtain sensor

- Measurement/counting/data detection safety light curtain sensor

- vehicle detection light curtain vehicle separator

- Safety laser scanner

- Pressure sensitive safety mat

- Safety edge sensor

- Safety Relay

- Photoelectric Sensors

- Slot type photoelectric switch

Safety light curtain sensor, safety light curtain sensor used to determine the position

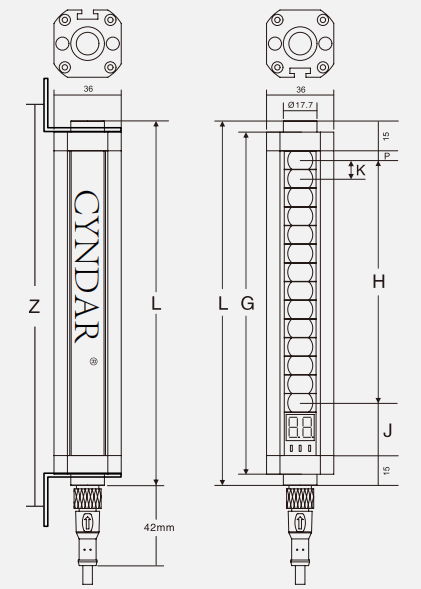

| Categories | CMT data detection/metering safety light curtain sensor |

|---|---|

| Brand | CYNDAR |

| Model | CMT |

| examination range | 30~3000mm, 30~6000mm |

| Light curtain type | Straight beam |

| voltage | DC 24V |

| Update Time | May 16,2024 |

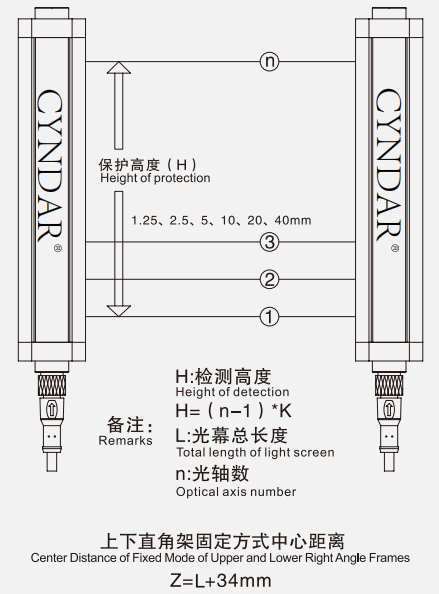

A light curtain safety device is an electronic device that senses changes in the light intensity it receives, including an optical system, amplifier and light curtain safety switch output device. All photoelectric sensors use modulated light to eliminate the possible influence of the surrounding light source. When working, the photoelectric sensor emits light. When the detected object passes by, depending on the detection mode, the object either absorbs light or reflects light to the safety light curtain sensor. The light receiver causes the intensity of the light received by the light receiver to change, and the change value triggers the switch signal output to realize the detection function.

1) Working principle: A transmitter and a receiver, infrared, when blocking any beam, it will give a signal to stop the device, thus playing a role of safety protection.

2) The safety light curtain can reduce the occurrence of accidents in terms of intrinsic safety, which is beneficial to the company itself, the operating workers and the society.

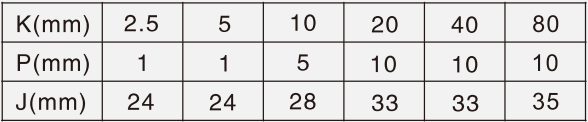

3) The density of the light beam determines how large the body part can be detected through the light curtain.

4) Safety light curtain sensor, safety light curtain sensor used to determine the position

- Loading...

- *Title

- *Content

- Safety light curtain safety grating sensor

- CCT universal safety light curtain sensor

- CRFT Waterproof Safety Light Curtain Sensor

- QX short-distance economical safety light curtain sensor

- CAT remote sensing safety light curtain sensor

- CST stamping safety protection safety light curtain sensor

- CSAT multi user detection mirror column safety light curtain sensor

- CBT/CZT ultra-thin compact safety light curtain sensor

- Measurement/counting/data detection safety light curtain sensor

- vehicle detection light curtain vehicle separator

- Safety laser scanner

- Pressure sensitive safety mat

- Safety edge sensor

- Safety Relay

- Photoelectric Sensors

- Slot type photoelectric switch

- Common Safety Devices on DevicesCommon Safety Devices on Devices

- Precautions for the use of safety matsPrecautions for the use of safety mats