Since 2010, Cyndar has been committed to safety sensors. We insist on technological innovation and put customer success first. A professional pre-sales team will guide customers on how to choose the most suitable products.

Announcement: Cyndar is tracking the company's actions in response to the COVID-19 crisis and improving best practices to incentivize better business behaviors. We voluntarily reduce profits to help companies through their sadness. We sincerely wish you health

curtain sensor Counting safety light barrier sensor to check shape

- Safety light curtain safety grating sensor

- CCT universal safety light curtain sensor

- CRFT Waterproof Safety Light Curtain Sensor

- QX short-distance economical safety light curtain sensor

- CAT remote sensing safety light curtain sensor

- CST stamping safety protection safety light curtain sensor

- CSAT multi user detection mirror column safety light curtain sensor

- CBT/CZT ultra-thin compact safety light curtain sensor

- Measurement/counting/data detection safety light curtain sensor

- vehicle detection light curtain vehicle separator

- Safety laser scanner

- Pressure sensitive safety mat

- Safety edge sensor

- Safety Relay

- Photoelectric Sensors

- Slot type photoelectric switch

curtain sensor Counting safety light barrier sensor to check shape

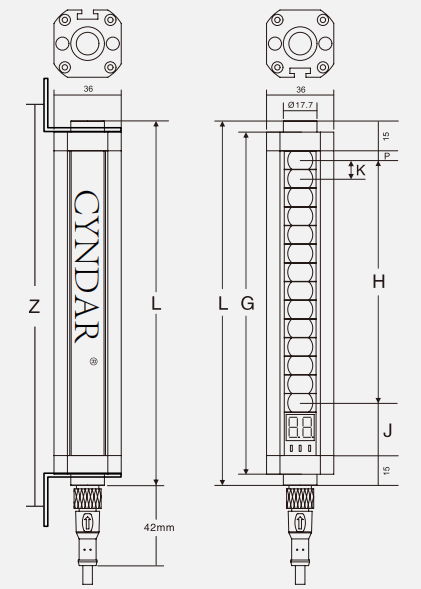

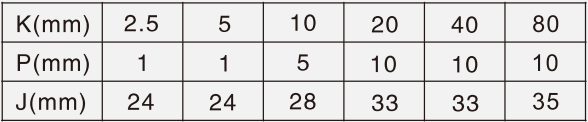

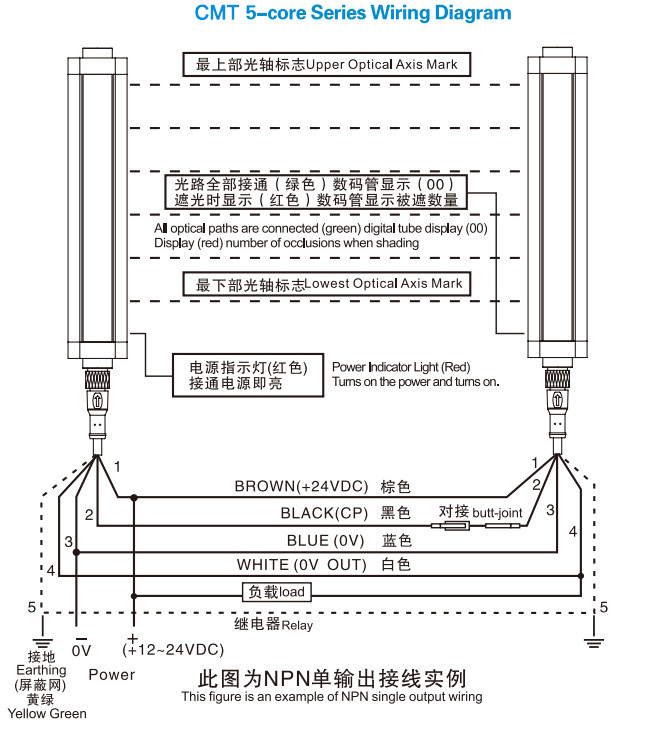

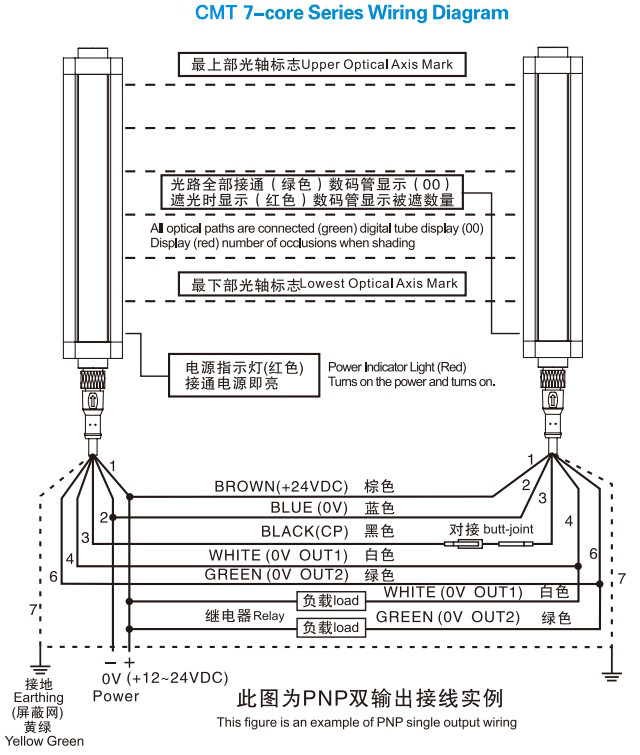

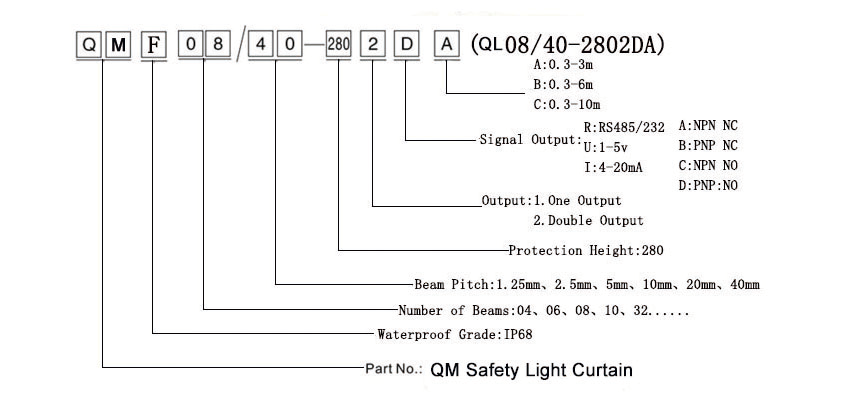

| Categories | CMT data detection/metering safety light curtain sensor |

|---|---|

| Brand | CYNDAR |

| Model | CMT |

| Reaction time | ≤15ms |

| scope of test | 30~3000mm, 30~6000mm |

| power supply | DC12/24V |

| Update Time | May 17,2024 |

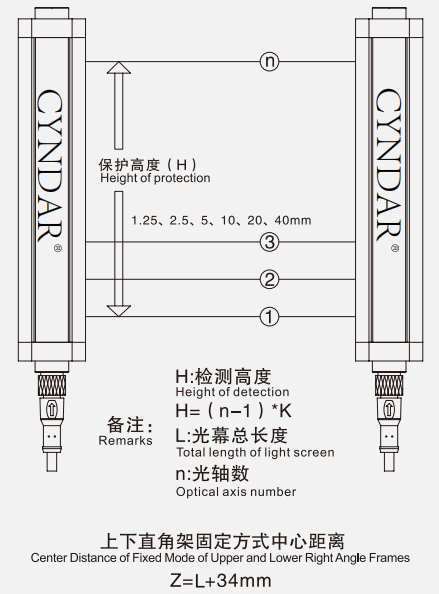

Response time: The response time of the light curtain system depends on when the light curtain sees the target object. When the beam channel blocked by the target object is exactly the beam channel currently scanned by the light curtain, the short response time is 15ms, and the response time is current 2 times the system scan time. The scanning time of the system depends on the height of the light curtain and the scanning mode.

1. Cover the safety light curtain with your hand and observe whether the indicator conversion is normal.

2. During the use of the punch light curtain safety device, the position of the photoelectric protection device shall not be changed at will.

3. In the protection zone, shield the laser curtain sensor by hand, and the machine should stop working immediately.

4. When the slider is at the bottom dead center (180 degrees), the light curtain is blocked, and the machine tool slider should be able to return.

5. For presses that can only achieve top dead center protection, when the slider stops at the top dead center and the slider blocks the ir light curtain, the next operation cannot be started.

- Loading...

- *Title

- *Content

- Safety light curtain safety grating sensor

- CCT universal safety light curtain sensor

- CRFT Waterproof Safety Light Curtain Sensor

- QX short-distance economical safety light curtain sensor

- CAT remote sensing safety light curtain sensor

- CST stamping safety protection safety light curtain sensor

- CSAT multi user detection mirror column safety light curtain sensor

- CBT/CZT ultra-thin compact safety light curtain sensor

- Measurement/counting/data detection safety light curtain sensor

- vehicle detection light curtain vehicle separator

- Safety laser scanner

- Pressure sensitive safety mat

- Safety edge sensor

- Safety Relay

- Photoelectric Sensors

- Slot type photoelectric switch

- Common Safety Devices on DevicesCommon Safety Devices on Devices

- Precautions for the use of safety matsPrecautions for the use of safety mats